views

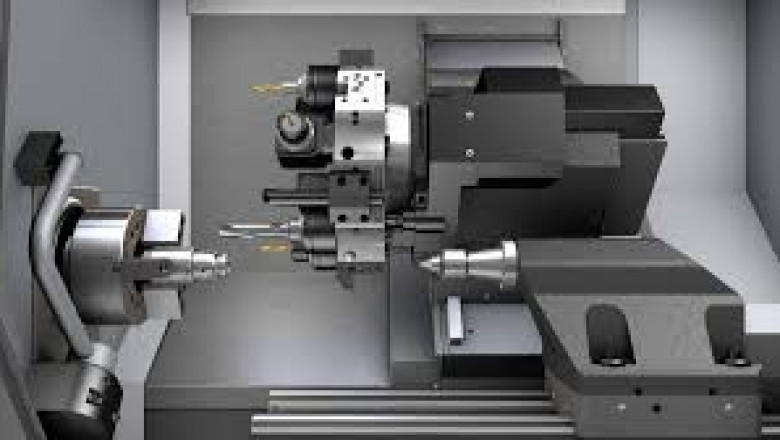

In today’s competitive manufacturing industry, precision and efficiency are vital for success. CNC (Computer Numerical Control) turning services play an essential role in producing high-quality parts with exceptional accuracy. However, many businesses often attempt to handle machining in-house, only to face issues that compromise product quality and production timelines. Recognizing when to seek professional help can save money, improve product outcomes, and increase operational efficiency. Below are five clear signs that indicate it’s time to consider a professional CNC Turning Service.

You’re Struggling with Consistency and Precision

One of the most evident signs that you need a professional CNC Turning Service is when your production output lacks consistency and precision. Variations in measurements, surface finishes, or part geometries can lead to significant product failures, costly recalls, or customer dissatisfaction. This inconsistency is often the result of using outdated or improperly calibrated machines, human error, or insufficient technical knowledge.

A professional CNC Turning Service employs advanced technology and experienced machinists to ensure repeatable accuracy on every part, regardless of volume. By outsourcing to a specialist, you eliminate many of the common variables that contribute to inconsistencies. High-end CNC machines offer micron-level precision, ensuring that every component matches exact specifications. Whether you're producing prototypes or large-scale batches, a trusted CNC Turning Service guarantees uniform results that meet industry standards.

You Have Tight Deadlines and Limited In-House Capacity

When deadlines are looming and your in-house team is stretched thin, it’s a strong indicator that you need external assistance. CNC turning projects can be time-intensive, particularly when you're managing other responsibilities like product design, assembly, and logistics. Trying to juggle all these tasks internally often results in delays, missed deadlines, and production bottlenecks.

A professional CNC Turning Service is equipped to handle tight schedules and large order volumes efficiently. These providers typically operate multiple machines and maintain streamlined workflows, enabling them to deliver high-quality parts quickly without sacrificing accuracy. By leveraging their capacity and expertise, you can meet customer demands on time and focus your internal resources on strategic activities like innovation and business growth.

Your Parts Require Complex Geometries or Tight Tolerances

If your components involve intricate shapes, fine details, or extremely tight tolerances, in-house machining may not suffice. Complex geometries often require multi-axis CNC turning machines, advanced software programming, and specialized tooling—resources that many smaller operations lack. Attempting to produce such parts without the proper setup can lead to frequent rework, increased scrap rates, and inconsistent quality.

Professional CNC Turning Service providers have the technology and technical know-how to tackle complex machining challenges with ease. They use advanced CAD/CAM software, multi-axis turning centers, and toolpath optimization to produce parts that meet strict specifications. Whether you need threading, grooving, contour turning, or multi-feature parts, a seasoned CNC Turning Service can deliver exceptional results while minimizing material waste and production time.

You’re Experiencing High Rejection Rates or Quality Control Issues

A high rejection rate in your production line is a major red flag that suggests deeper quality control problems. When parts fail to meet design specifications or quality assurance standards, it not only impacts your bottom line but also damages your reputation with clients. Common culprits include inexperienced operators, worn-out tools, and inadequate inspection processes—all of which are common in non-specialized environments.

By partnering with a professional CNC Turning Service, you gain access to rigorous quality control systems and certified machining practices. These services typically include in-process inspection, final dimensional checks, and documentation that verifies conformance to tolerances. Their commitment to quality ensures that each part is manufactured to the highest standard, reducing returns and ensuring that your products function as intended in their final applications.

You Want to Reduce Costs and Improve Efficiency

At first glance, outsourcing to a CNC Turning Service might seem like an added expense. However, when you factor in the cost of purchasing CNC machinery, hiring skilled technicians, maintaining equipment, and managing production overhead, the economics start to favor outsourcing. In many cases, trying to produce parts in-house actually results in higher per-unit costs, particularly for low-to-mid volume production runs.

A professional CNC Turning Service allows you to scale production without investing in expensive capital equipment. You only pay for the parts you need, when you need them, and benefit from the provider’s economies of scale. Additionally, professional machinists often suggest design improvements or material substitutions that can further reduce manufacturing costs. By outsourcing, you improve cost-efficiency, increase flexibility, and gain a competitive edge in the market.

Conclusion

CNC turning plays a critical role in modern manufacturing, offering precise, repeatable, and efficient solutions for component production. If you're dealing with inconsistent results, capacity issues, complex part requirements, high rejection rates, or rising costs, it's time to consider outsourcing to a professional CNC Turning Service. With access to cutting-edge machinery, skilled operators, and quality assurance systems, a specialized service provider can transform your production process and elevate your end products. Making the strategic choice to partner with a CNC Turning Service not only solves current pain points but also positions your business for long-term success and innovation.

Comments

0 comment